WAAMpeller: World First Class-Approved 3D Printed Ship’s Propeller

A consortium of organizations are working toward a landmark achievement in the maritime sectors: creating the world's first class-approved 3D-printed ship's propeller.

As many sectors of the shipbuilding industry suffer due to overcapacity, it is this type of innovative leap that will -- if successful -- separate the next generation of leaders in the sector. In the effort a cooperative consortium of Damen Shipyards Group, RAMLAB, Promarin, Autodesk and Bureau Veritas aim to develop the world’s first class approved 3D printed ship’s propeller, dubbed WAAMpeller.

“Three students from Delft Technical University were investigating the potential of 3D printing for us. They brought us into contact with the other members of the consortium,” said Kees Custers, Project Engineer in Damen’s Research & Development department, explaining his organization's involvement in the project for the past year. “What is quite unique about this group of five companies is that, while we have joint interests, we also have individual aims. This leads to a very productive and cooperative atmosphere in what is a very exciting project.”

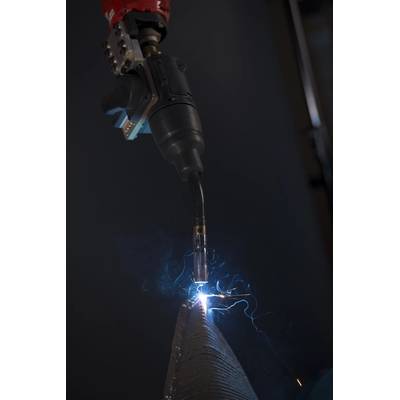

The propeller will be based on a Promarin design that is typically found on a Damen Stan Tug 1606. This 1,300mm diameter propeller weighs approximately 180kg. Using Autodesk software in the construction process, Port of Rotterdam’s RAMLAB will fabricate the WAAMpeller from a bronze alloy using the Wire Arc Additive Manufacturing (WAAM) process.

Bureau Veritas will be involved in the certification of the completed product; in what will be the first time that a metal 3D printed maritime component will be approved by class.

Once the propeller has been printed, Damen’s role will continue with full-scale trials. “We will be performing a comprehensive programme that will include bollard pull and crash test scenarios. Our ambition is to demonstrate that the research phase for 3D printing in the maritime sector is over, and that it can now be effectively applied in operations.”

The first propeller is expected to be printed by summer 2017, with subsequent testing occurring in the autumn.