Navigating Marine Connectivity

The NMEA (National Marine Electronics Association) 2000 standards helped create a framework for safer, more reliable marine communications by streamlining the connectivity of boat engines, navigation, control, power distribution, water, waste and other mechanical and monitoring systems. Onboard connectivity translates into improved operator safety, better diagnostics, simplified maintenance and lower lifetime costs. Manufacturers recognize the value of electronics to distinguish their brand—and satisfy customers seeking connectivity at sea.

Built for a life at sea

Signal integrity, data management and electrical voltage grounding are a few of the challenges to designing the connected boat. Reliability and safety depend on the integrity of power and signal connections that must perform unfailingly regardless of ambient conditions. That is why it is important to use robust products to create reliable integrated onboard networks with the lowest installed costs over time.

Molex connectivity solutions develop content-rich on-board applications and digital equipment and meet demand for higher data speeds and bandwidth. From navigation systems, bilge pumps and fish finders to conveniences like hot water heaters, refrigerators and high-speed Ethernet, Molex IP-rated connectors assure that onboard systems are built for a life at sea.

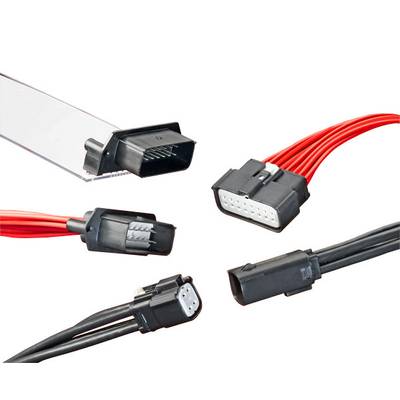

A portfolio of Molex sealed quick disconnects, high-speed connectors, terminators and power products have been tested and validated to withstand extreme vibrations, temperature and saltwater exposure. These powerful technologies support electrical and network platforms including marine engine controls, instrumentation panels, navigation equipment, power steering and autopilot systems, body electronic modules and dockside charging systems.

Redefining sealed marine connections

Rugged marine solutions start with the right sealing technology. Salt water, fuel, cleaning chemicals and other contaminants can lead to electrical system malfunctions and failures if connection system seals are ineffective or compromised.

The ML-XT Sealed Connection System offers reliability for critical wiring applications in harsh environments. The two-shot LSR (liquid-silicone rubber) molding and recessed rear seals combine to lock out the contaminants of engines, pumps and other marine operations. The covalent bond between the seal and the connector body permanently connects the two components at a molecular level.

The ML-XT system mitigates seal positioning and movement problems. The HCR (high-consistency rubber) recessed rear seals completely resist movement during cable routing. Protected by a rigid back cover, the seal allows flexible cable movement and its recessed, fixed nature reduces the possibility of leak-paths found in traditional designs. The unique 18-circuit ML-XT sealed system, with field-proven XRC terminals, color-coded housings and custom options, ships fully assembled—ready to deliver full IP68, IP69K and SAE J2030 compliance.

High-speed bandwidth on the high seas

Onboard connections must be able to be quickly connected and disconnected without risk of misaligned mating or lost signal or power. A wide variety of keying and cabling options, in addition to compact size and rugged sealing make the M12 a mainstay technology—and an NMEA OneNet recommended connector for marine applications.

Traditional threaded M12 connectors are screwed into place to achieve a secure connection. Molex product extensions include an Ultra-Lock push-pull locking mechanism rated to IP69K. Ultra-Lock provides a push-to-lock mechanism allowing the user to simply push the M12 connector to secure the plug and receptacle. Anti-vibration features prevent the coupler from loosening, even under extreme vibration. Ultra-Lock makes the M12 fast and easy to use, while creating a secure seal that can only be disconnected by grabbing onto the built-in coupler.

The Molex Brad Micro-Change M12 CAT6A System, which delivers signal integrity and up to 10Gbps Ethernet for high-speed data transfer (up to 500MHz) applications in harsh environments. The innovative cross shielding is the next development in speed with a form factor half the size of sealed CAT6A RJ45 connectors.

Other Sealed Marine Interconnects

A wide range of other Molex sealed interconnects meet the application requirements for ruggedized marine plugs, receptacles and power connectors.

- MX150L Industrial Sealed Connector System:

The sealed MX150L system is designed for power and low-level signal applications, such as power trim equipment, stove, refrigerator and heads, and more challenging applications such as throttle control, bilge pumps, water pumps, bow thrusters and outboards. Integral terminal positioning assures MX150L crimped terminal leads are securely locked into the connector.

- SRC (Sealed Rectangular Connector) and XRC (Extra Rugged Circular) Connectors:

The SRC interconnect provides a rugged, environmentally sealed system supporting low-level signals and currents up to 40.0A per contact. IP67-rated XRC sealed plugs and receptacles are suited for heavy-duty applications requiring protection against dust, water and other contaminants.

- Quixon Quick Disconnect Terminals:

Quixon quick disconnect terminals provide manufacturers of marine instrument panel gauges and switches with a self-aligning feature for simple, secure connections with lower insertion force and greater blind-mate capability versus standard terminals.

- Perma-Seal Terminals and Splices:

For bilge pumps, windlass, windshield wipers and other marine applications, Perma-Seal terminals and splices provide an environmentally sealed connection for 8 to 22 AWG wire. Using a special compound that shrinks quickly at a lower temperature, Perma-Seal insulates and protects joints from abuse, abrasion, water, salt and corrosive compounds that can cause serious problems for conventional, unsealed splices.

- Self-Contained Power Connectors (SCPC):

A timesaving alternative to hard wiring junction boxes for the main panel and harness, hot water heaters, battery chargers and other marine equipment, a SCPC system can be used to splice and tap solid and stranded non-metallic sheathed cable, providing fast, easy connection of boat cables. Molex SCPC connectors support two and three conductors and ground circuits for AC power applications. The design eliminates wire nuts and junction boxes for traditional splicing applications, and enables splicing together of two cable segments quickly and reliably.

Quick and reliable are key characteristics for all connectivity in marine equipment. In harsh, heavy vibration conditions, connectors are at a higher risk of being jarred loose, or exposed to corrosive salt, lubricants and other chemicals, which can lead to hours of diagnostics chasing down network failures to prevent potentially more serious problems.

The Author

Kurt Krutsch is product marketing manager for the commercial vehicle industry at Molex. He is an NMEA, ABYC and NMMA member and is responsible for new product development to support customer and industry standards needs. He has been with Molex for 19 years.